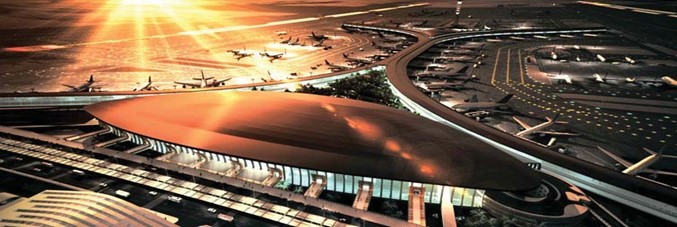

King Abdel Aziz International Airport

Client: General Authorities of Civil Aviation.

Location: King Abdel Aziz International Airport, Jeddah, KSA.

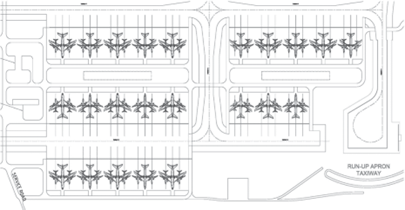

Project: New Jet Fuel Hydrants Network at KAIA Development Phase- 1.

Main Contractor: Saudi Binlading Group-Architecture & Building Division.

Aprons Contractor: Almabani General Contractors

Fuel Aviation Network Contractor: Amana Pipelines Construction

Fuel Aviation Network Contract Administrator: Aleph International

Fuel Aviation Network Project Management & Cost Control: Multitech International

Consultant Engineer & Client Rep: Dar Al Handasa

End User: GACA-ARAMCO-APSCO

Project Description

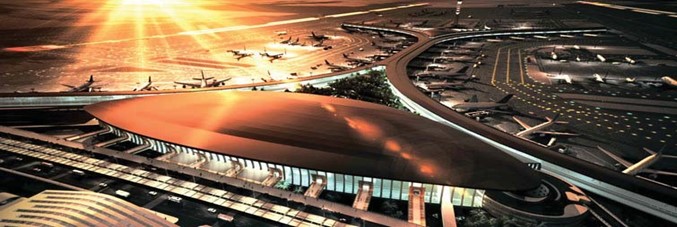

King Abdul Aziz International Airport (KAIA) is located approximately 25 km North of Jeddah and has since become the busiest and the fastest growing airport in the Kingdom of Saudi Arabia, providing commercial operations and acting as the gateway to the holy cities of Makkah and Madinah. The existing infrastructure and facilities are inadequate to cope with increasing demand; KAIA requires major expansion and upgrading of its existing infrastructure and facilities.

The Government of the Kingdom of Saudi Arabia, Ministry of Defense and Aviation and Inspectorate General, General Authority of Civil Aviation are expanding KAIA which shall take place in three (3) Development Phases: the first phase, for 30 million passengers capacity, is scheduled to be completed by 2014; the second phase, for 43 million passengers capacity, by 2020; and the final phase, for 80 passengers capacity, by 2035.

Scope of Work:

- Supply, Install & Commission of 32 Km of Jet A1-fuel Hydrant System comprising of fuel pipes ranging from 12″ to 24″ in diameter and comprising over 400 hydrants API standard hydrant pits, under hydrant valves and hydrant valves, over 80 double Block & Bleed (DB&B) valves ranging in size from 8″ to 24″ in diameter.

- Supply, Install & Commission of 16 Km of 24” and 12 Km of 20 “ Jet A1-supply line connecting the ARAMCO bulk Farm to the existing Airport fuel farm and the newly built fuel farm and the loops for apron stands around the newly built terminal and cargo aprons.

- Supply, install & Commission of new re-fuller station and into plane network.

King Abdel Aziz International Airport

Client: General Authorities of Civil Aviation.

Location: King Abdel Aziz International Airport, Jeddah, KSA.

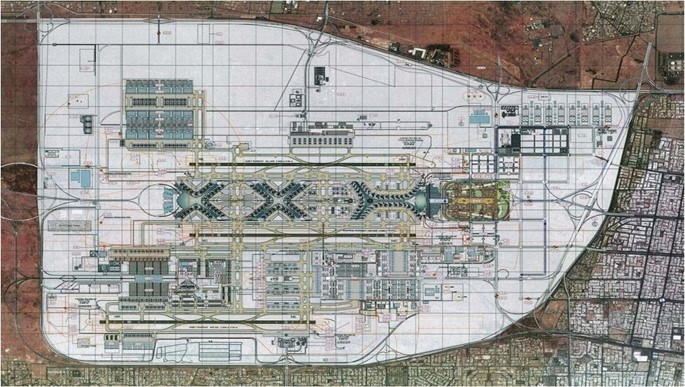

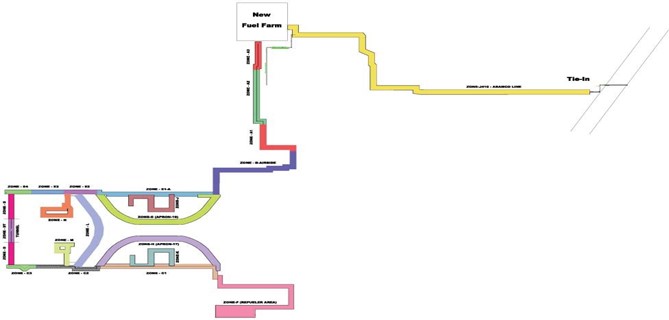

Project: New Jet Fuel Hydrants Network-Tie-In-Cleaning, Testing and Flushing.

Main Contractor: Saudi Binlading Group-Architecture & Building Division.

Aprons Contractor: Almabani General Contractors

Fuel Aviation Network Contractor: Amana Pipelines Construction

Fuel Aviation Network Contract Administrator: Aleph International

Fuel Aviation Network Project Management & Cost Control: Multitech International

Consultant Engineer & Client Rep: Dar Al Handasa

End User: GACA-ARAMCO-APSCO

Project Description

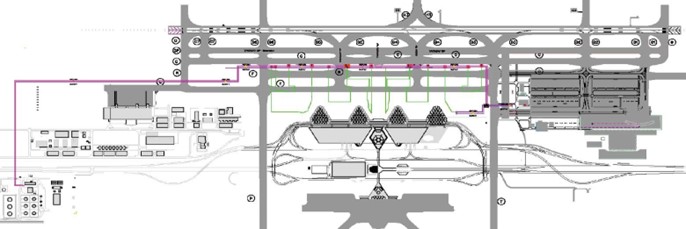

King Abdul Aziz International Airport (KAIA) is located approximately 25 km North of Jeddah and has since become the busiest and the fastest growing airport in the Kingdom of Saudi Arabia, providing commercial operations and acting as the gateway to the holy cities of Makkah and Madinah. The existing infrastructure and facilities are inadequate to cope with increasing demand; KAIA requires major expansion and upgrading of its existing infrastructure and facilities. The Government of the Kingdom of Saudi Arabia, Ministry of Defense and Aviation and Inspectorate General, General Authority of Civil Aviation are expanding KAIA which shall take place in three (3) Development Phases: the first phase, for 30 million passengers capacity, is scheduled to be completed by 2014; the second phase, for 43 million passengers capacity, by 2020; and the final phase, for 80 passengers capacity, by 2035.

Work Description:

The existing fuel farm and the military base are receiving fuel from the North Jeddah ARAMCO depot alternatively through two 20” feed lines and one 6” line. The newly built Into-plane network and Fuel farm are to be connected to the existing network by Tying-In in sequence to the live supply lines at 6 particular locations without interrupting the fueling operations of the existing running airport. Cleaning, Air blowing, Pressure testing, hydro testing, purging and drying of the network are conducted by the time the Tie-In is completed and the network is ready to receive fuel for filling, soaking and flushing operations.

Scope of Work:

Tie-In Works:

- De-gazing of Line 1 ARAMCO (under pressure) supply line. Line 1 will feed the new fuel farm by pressure.

- Tie in to line 1 and the bypass to allow fuel to feed back to the existing fuel farm.

- De-gazing of line 2 (gravity line) supply line.

- Tie-In to line 2. Line 2 will feed the existing fuel farm by gravity until the new farm is fully operational.

- Tie-In 6 inch feeding the Military base.

- De-commissioning of the existing fuel farm.

Cleaning, Pressure Testing and Flushing works:

- Cleaning, Air Blowing, Pressure test D300-Hydrant Network by sections

- Cleaning, Air blowing, Hydro-test, purging and drying J410 supply line from Tie-In to the newly built fuel farm

- Filling, soaking and flushing of the networks alternatively by sections.

King Khaled International Airport

Client: General Authorities of Civil Aviation.

Location: King Khaled International Airport, Riyadh, KSA.

Project: Fuel Hydrants Network At New Aprons to the East of the Commercial Galleries at KKIA.

Consultant Engineer & Client Rep: Saudi Consult.

Main Contractor: Almabani General Contractors.

Fuel Aviation Network Contractor: Amana Pipelines Construction

Fuel Aviation Network Contract Administrator: Aleph International

Fuel Aviation Network Design Review, Project Management & Cost Control: Multitech International.

Fuel Aviation Network Design: HansaConsult.

End User: GACA-ARAMCO-APSCO.

Project Description:

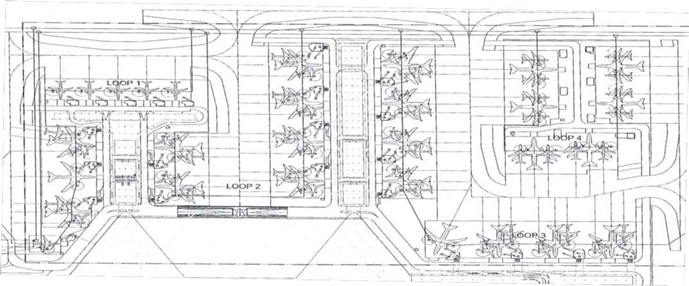

The project consists of the extension of the fuel hydrant system for the New Remote Apron of King Khalid International Airport. The scope of work covers the design and built of the new supply loops and hydrant network, valve chambers and the TIE-IN connection between the existing fuel supply lines of the Existing East Remote Apron and the New Remote Apron, in addition to the design and detailed engineering for Apron The new system to have a Tightness Control System. Scope includes design, build and implementation of the full control philosophy for the hydrant system, SCADA & ESDB system to be monitored from ARAMCO control room. Testing, commissioning, and flushing of the new hydrant system.

Two types of stands are planned: Code F/2C designed to accommodate 1 code F aircraft, 1 code E,D,C aircraft or 2 code C aircrafts simultaneously. Code E/2C designed as above except that they are not suitable for Code F.

Scope of Work:

- Engineering, Procurement, Construction & Commissioning (EPCC) of the new Fuel Hydrant Systemز

- Supply, Install & Commission of Jet A1-fuel Hydrant System comprising of fuel pipes ranging from 12″ to 24″ in diameter. Supply, Install & Commission hydrants comprising of API standard hydrant pits, under hydrant valves and hydrant valves, double Block & Bleed (DB&B) valves ranging in size from 12″ to 24″ in diameter.

- CP works including supply, installation, testing of temporary and permanent CP system for Hydrant Network

- Supply, Install & Commission Emergency Shutdown (ESD) System.

- Supply, Install & Commission Tightness Control System (TCS).

- Cleaning, Filling, Soaking, Flushing of fuel hydrant network, and Start-up of control and monitoring system.

King Khaled International Airport

Client: General Authorities of Civil Aviation.

Location: King Khaled International Airport, Riyadh, KSA.

Project: Upgrade, Runway, Taxiway and Airplane Parking At King Khaled.

Consultant: AECOM.

Main Contractor: Almabani General Contractors.

Fuel Aviation Network Contractor: Amana Pipelines Construction.

Fuel Aviation Network Design Review, Project Management & Cost Control: Multitech International.

Fuel Aviation Network Design: HansaConsult.

End User: GACA-ARAMCO-APSCO.

Project Description:

The King Khaled International Airport is currently undergoing a large development and expansion program that aims at increasing capacity in the near future. Serving the city of Riyadh, it is the second biggest airport in Saudi Arabia, after Jeddah Airport. Some 20 million passengers per year travel through the airport and the current expansion program will extend capacity to 35 million. As part of this program, the General Authority of Civil Aviation (GACA) of the Kingdom of Saudi Arabia has awarded Almabani General Contractor the contract for the design and construction of the required enhancements. Egis was nominated as design consultant of Almabani. For the first time in the airport infrastructure domain Egis will perform the full design under the BIM (Building Information Modeling) concept. Egis will also provide full technical support during construction. The scope of works for this project covers the following airside facilities: new taxiways; new cargo apron; rehabilitation of existing taxiways; extension of the existing fuel line; and miscellaneous drainage improvements.

Scope Description:

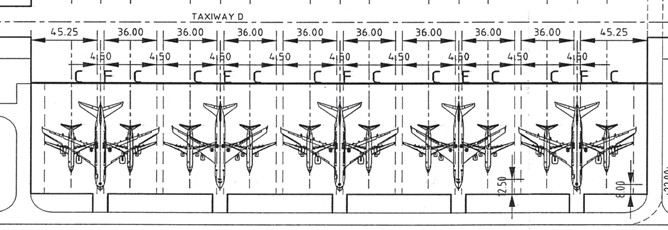

The new parking stands shall be equipped with new fuel hydrants. The existing two main fuel feeder lines, 24” each, crossing this apron shall be removed. Phasing of this removal needs to be coordinated with the installation of the new main lines such that disturbance of normal operations will be minimized. Continuous supply of fuel from jet fuel lines to airport facilities must be maintained at all times. The new 24 inch dual, flow and return, main fuel lines inclusive of chambers and valves, complete with blank flange connections for the Terminal fuel loops shall be installed inclusive of all connections to existing intake (landside) and output (airside) points such as to ensure a complete and compatible jet fuel system.

Scope of Work:

- Design and Detailed Engineering Mechanical works for the Jet A-1 Fuel Supply & Hydrant System.

- Design and Detailed Engineering Electrical & Instrumentation for the Jet A-1 Fuel Supply & Hydrant System.

- Supply and install jet fuel piping system including necessary fittings, valves, bends, elbows, hydrant valve pits & covers, low points and high point pits and covers, leveling and NDT testing.

- Supply & Install TCS Leak Detection System for the Main Fuel Pipe up to the Branch Valve Chambers for future Loop Connections in T1-T4. Supply & Install SCADA/PLC Specific Software for the New Main Fuel Pipe.

- Supply & Install temporary and permanent Cathodic Protection System.

- Supply & Install, new Hydrants at Cargo Apron Extension (Motorized Hydrant Valves) & removal of the existing decommissioned pipes.

- Cleaning, blowing, Pressure testing, hydro-test, drying, purging, filling, soaking, flushing, testing, commissioning & Start up.

King Khaled International Airport

Client: General Authorities of Civil Aviation.

Location: King Khaled International Airport, Riyadh, KSA.

Project: New T3 / T4 Passenger Terminal, Fuel Hydrants Network.

Design Team Leader: HOK.

Main Contractor: HOCHTIEF Solutions AG – Germany.

Fuel Aviation Network Contractor: Amana Pipelines Construction.

Fuel Aviation Network Contract Administrator: Aleph International.

Fuel Aviation Network Design Review, Project Management & Cost Control: Multitech International.

Fuel Aviation Network Design: HansaConsult.

End User: GACA-ARAMCO-APSCO.

Project Description:

Thirty years after designing King Khalid International Airport (KKIA), HOK has been nominated the design team leader for the expansion of Terminals 3 and 4.This expansion will enable the airport to meet increasing demand and support the country’s growing economy. As with the original airport, the design creates a strong sense of place and a passenger-friendly terminal welcoming each traveler as an important guest to Riyadh. When HOK designed the four terminal buildings in the 1980s, one was left as an empty building shell. The design brief for the current project was to integrate and extend Terminals 3 and 4 as an infill development that complements and enhances the existing airport while accommodating 17.5 million passengers per year. The project also introduces a central processor building and three new piers with 24 gates. The integrated design solution responds to Riyadh’s culture while providing memorable spaces. The hexagonal roof form and triangular organization of the original buildings guided the design. By basing the plan on the original module size, the team designed a seamless intervention with no clear distinction between old and new. Sustainable strategies include replacing the existing terminals’ external cladding with a high-performance facade system and upgrading infrastructure with two new energy centers. An integrated BIM strategy allows the entire design team to rationalize and coordinate the process throughout construction. The facilities are being refurbished in two phases to allow the existing airport operations to function at capacity during construction.

The Fuel Network Scope consists of the design, supply and installation of the extension of the hydrant refueling system to serve the apron layout of terminal 3 & 4. Four new hydrant loops will be installed and connected to existing fuel mains installed during phase 1A located between Taxiway G and new aprons at the north end.

Scope of Work:

- Engineering, Procurement, Construction & Commissioning (EPCC) of the new Fuel Hydrant System.

- Supply & Install of Jet A1-fuel Hydrant System Network and hydrants comprising of API standard hydrant pits, under hydrant valves and hydrant valves, double Block & Bleed (DB&B) valves.

- CP works including supply, installation, testing of temporary and permanent CP system for Hydrant Network.

- Supply, Install & Commission Emergency Shutdown (ESD) System & Tightness Control System (TCS).

- Supply and install Automatic control and monitoring system.

- Cleaning, Filling, Soaking, Flushing of fuel hydrant network.

- Demonstrate the operation of the complete systems and train personnel for their use.

King Khaled International Airport

Client: General Authorities of Civil Aviation.

Location: King Khaled International Airport, Riyadh, KSA.

Project: Fuel Hydrants Network Apron 5 Terminal 5 at KKIA.

Consultant Engineer & Client Rep: AECOM.

Main Contractor: TAV Construction & Al Arrab General Contracting.

Fuel Aviation Network Contractor: Amana Pipelines Construction.

Fuel Aviation Network Design Review, Project Management & Cost Control: Multitech International.

Fuel Aviation Network Design: HansaConsult.

End User: GACA-ARAMCO-APSCO.

Project Description:

TAV Construction has won a $400m design and construction tender for the construction of new Terminal 5 at King Khaled International Airport in Riyadh, Saudi Arabia. Collaborating with Al Arrab Contracting, TAV will construct a 100,000m² passenger terminal, a 90,000m² multi-story car parking to accommodate 3,000 cars, a fire station, an operations center and a plane apron, in addition to terminal airside infrastructure. The 18-month project will also include elevated roads and infrastructure works to link the new Terminal-5 to the existing terminals.

Scope Description:

The project consists of the extension of the fuel hydrant system for the New Remote Apron of King Khalid International Airport. The scope of work covers the supply, delivery, installation of the complete hydrant system including, testing, commissioning, coordination of services and the tie-in into the existing system together with all start-up activities. The new system to have a Tightness Control System. Scope includes design, build and implementation of the full control philosophy for the hydrant system, SCADA & ESDB system to be monitored from ARAMCO control room.

Scope of Work:

- Engineering, Procurement, Construction & Commissioning (EPCC) of the new Fuel Hydrant System.

- Supply, Install & Commission of Jet A1-fuel Hydrant System comprising of fuel pipes ranging from 12″ to 24″ in diameter. Supply, Install & Commission hydrants comprising of API standard hydrant pits, under hydrant valves and hydrant valves, double Block & Bleed (DB&B) valves ranging in size from 12″ to 24″ in diameter.

- CP works including supply, installation, testing of temporary and permanent CP system for Hydrant Network.

- Supply, Install & Commission Emergency Shutdown (ESD) System & Tightness Control System (TCS).

- Cleaning, Filling, Soaking, Flushing of fuel hydrant network, and Start-up of control and monitoring system.